Elomatic is an international consulting and engineering company that provides top-level expert services, products and turnkey solutions to process, machinery, marine, energy and pharmaceutical industries. We are focused on continuous improvement and sustainable development, and we are committed to design solutions that increase the wellbeing of people and the environment. Established in 1970, Elomatic employs 1,300 professionals, and has customer in more than 80 countries across the globe.

Elomatic marine can serve as your partner in the design and construction of ship and offshore wind power solutions with expertise in environmental requirements.

We have extensive experience and an established role as an early adopter of new technologies. We offer a full range of design and project management services for different types of vessels.

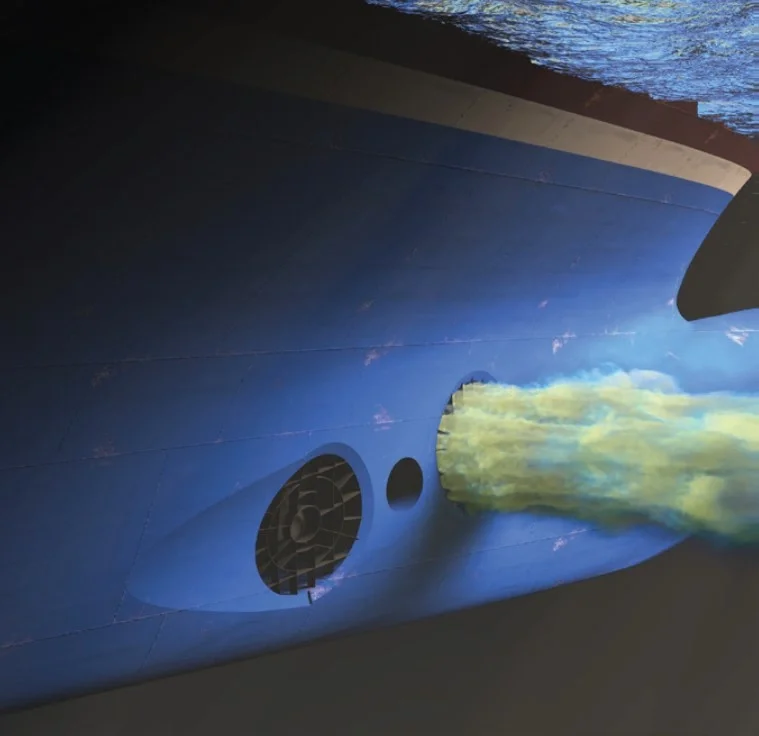

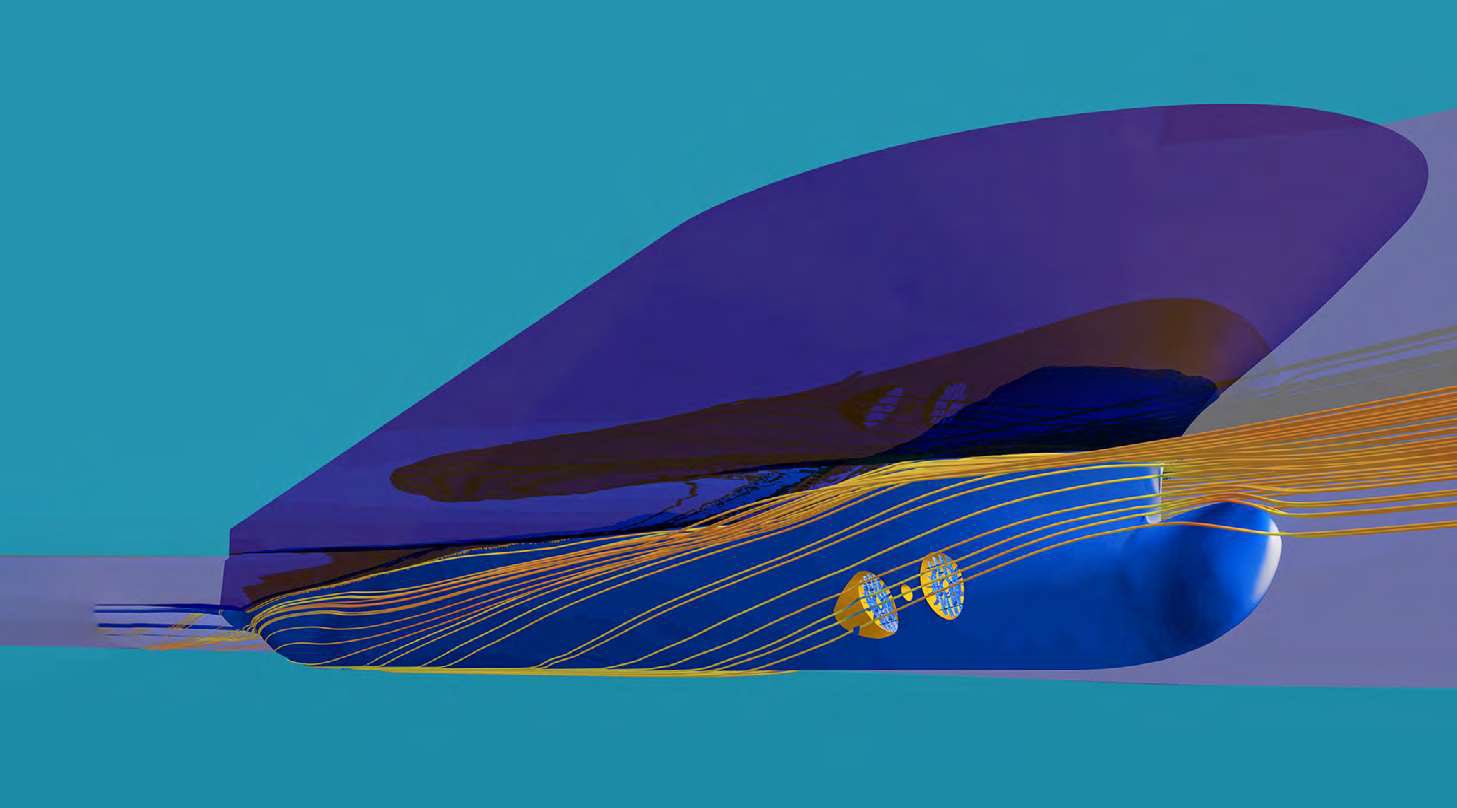

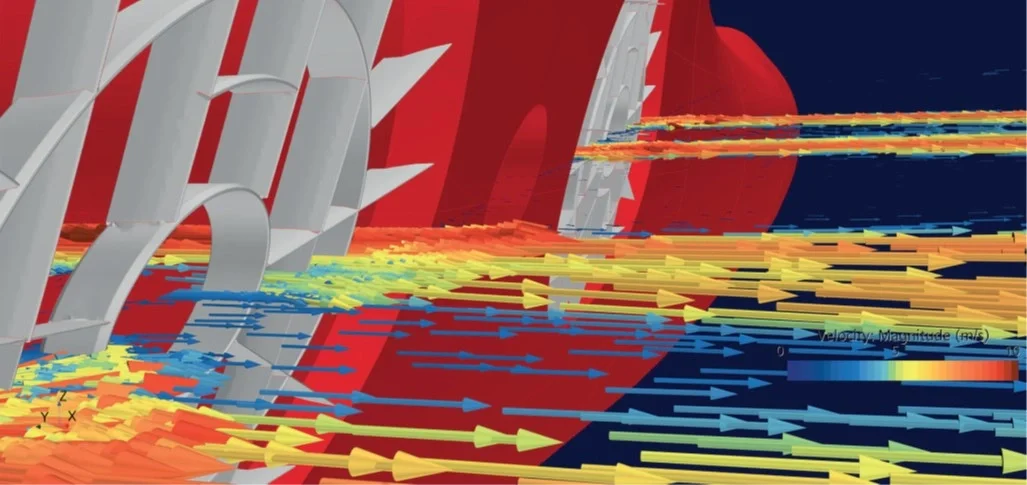

Reduce fuel consumption and increase your vessel’s propulsion power with our Elogrid solution.

Minimize offshore wind power plant cost with our innovative and environmentally friendly Float Foundations solution

Shipowners and Operators

We develop innovative solutions that can minimize the environmental impact and operating costs of your ships.

With competence accrued from years of experience, we can help tackle your business challenges. For example, our Elogrid solution significantly reduces the additional resistance and fuel consumption of ships. We carry out projects ranging from small consulting tasks to comprehensive ship design projects. Our range of competencies is vast and covers, for example, hydrodynamics, machine solutions and usability.

We have special expertise in new fuel types, such as green hydrogen, ammonia and methanol. We can research fuel availability or alternative machinery solutions while considering all safety aspects.

Services for Shipowners and Operators

- Elogrid™

- Ship design

- Decarbonization

- Ship performance simulations and analysis

- Upgrades, enhancements and life extensions

Offshore Energy

We offer innovative solutions and consulting related to offshore wind power and the transition to carbon-neutral fuels. Our foundation solution, Float Foundation, allows you to install an offshore wind farm without special vessels.

We have developed an innovative foundation solution for offshore wind farms. Float Foundation allows you to avoid expensive offshore lifting while setting up an offshore wind farm. As a result, you no longer have to rely on the availability of special windfarm installation vessels. The environmentally friendly solution is suitable even for very shallow waters.

In addition, we offer a platform solution for the transformer stations located near the wind farms, as well as consulting for the assembly of floating wind turbines. We also help you in your new business, from fuel production and distribution to utilization onshore, offshore or onboard.

Services for Offshore Energy

Shipbuilders

You can utilize our strong experience for all types of vessels. We design cost-effective, energy-saving solutions for your ship projects and can reliably carry out even the largest projects.

Whether you are looking for ship design services or help in developing dockyard processes, we have the experts you need. We have successfully completed numerous significant projects. We operate globally and find the best solutions for different environments.

We have more than 50 years of experience in the marine industry, and our expertise covers various types of ships, from cruise liners to government vessels and icebreakers. We offer you a full service that includes technical analysis and visualization in addition to ship design. If required, we can also take care of the interface between design and production.

Services for Shipbuilders